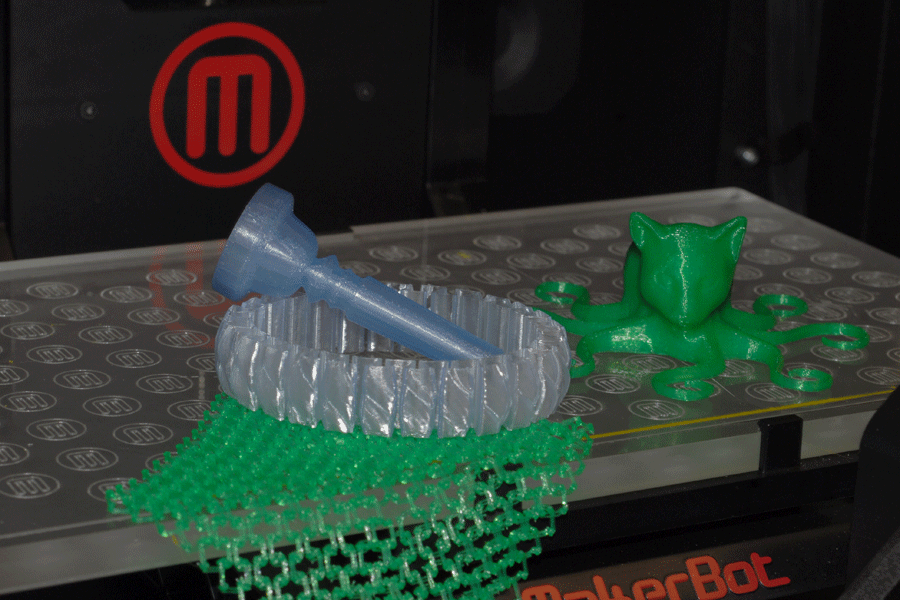

Through a generous donation and some help from their own budget, Lakeland College’s Computer Science Department was able to purchase a MakerBot II 3D printer last year.

Since then, the students in the Lakeland chapter of the Association of Information Technology Professionals (AITP) have been working with the printer by testing, creating 3D test models from downloaded content and experimenting with different software to create original 3D models.

The printer is located in the AITP computer lab in Chase 216, and the room contains several of its semi-transparent 3D models, including a miniature replica of Lakeland’s sign at the corner of County A and County M.

“The Board of Directors thought that would make a nice gift to the donor of the new sign,” said Cynthia Lindstrom, assistant professor of computer science. “The students have been working outside of class time to make these prototypes.”

The plastic is fed into the printer in long, thin ropes that come off of a spool. In simplest terms, the printer softens the plastic until it can be applied at a thickness of 100 microns—smaller than a human hair. The models are printed by a precision robotic tip that is directed by a computer across a single plane at a time. The tip also moves on the z-axis because the models are built layer by layer. Each 100 micron-wide plane gets a slightly different set of lines printed onto it, and slowly, a complete model is built.

“In the next prototype we’ll work on adding more detail in 123d Design,” President of Lakeland’s AITP chapter and senior computer science major Brian Winter said, referring to the latest software the chapter uses, Autodesk 123d Design. “We’re also working … to find a paint that will stick to this kind of plastic.”

“We just got the scanner hooked up last week,” Lindstrom said. The 3D scanner was donated a few weeks ago by the Bemis Manufacturing Company from Neenah, Wisconsin.

Winter and others in Lakeland’s AITP chapter have been working to calibrate and set up the scanner.

Lindstrom hopes to use the 3D printer in a classroom setting in the near future, but for now, all learning surrounding the printer is done outside of class time. At night, the AITP chapter has free reign of the computer lab in Chase 216. Many of the new members learn from those who worked with the printer last year. It seems to be an effective way to learn, as exemplified by the plethora of 3D models on display in the room.

“The next project will probably be to make shot glasses and sell them,” Winter said, referring to the AITP chapter’s future plans for the new printer.

The group has other ideas for fundraising as well, including a snowflake Christmas ornament they have been prototyping. They hope the printer will prove to be an essential fundraising tool in the near future.